DNC Communication

for CNCs, Robots, PLCs and more

For over a decade CIMCO DNC-Max has been the leading DNC solution by which all others must be compared. From its best-in-class client/server architecture to its unmatched configurability and scalability. DNC-Max meets the requirement of both small shops and corporate enterprises with thousands of machines in multiple remote facilities.

Video: DNC-Max – Product overview (3:16 min)

Benefits

Network CNCs, PLCs & Robots

Connect all your manufacturing equipment in one network using industry standard hardware, including Ethernet and Wireless serial device servers, traditional card based hardware, and existing legacy hardware.

Works with your files

Whether you set up your first DNC system or you replace an existing, the DNC application you choose must be compatible with your data. DNC-Max eliminates the need to update all your existing NC programs.

Access programs immediately

With DNC-Max there is no waiting. All your machines can download programs at the same time.

Download programs remotely

Reduce downtime from walking programs out to the shopfloor. Initiate downloads of part programs directly from the machine’s CNC control, from any modern mobile device or using a Barcode reader.

Ease of use and administration

File transfers, port monitoring and system administration are all performed in a clean, intuitive client/server interface which is part of the system’s intelligent, solution driven design.

A scalable solution

DNC-Max scales with your company. Upgrade with integrated manufacturing file management (CIMCO NC-Base/MDM) and manufacturing data collection & machine monitoring (CIMCO MDC-Max).

DNC-Max gives you full control over program transfers from a central application and provides full compatibility with your existing machines and files. With Remote Request, transfers can be initiated from the CNC control or mobile device to limit time wasted from walking programs out to the shopfloor. Dynamic feedrate and spindle speed adjustment, auto-receive, parameter offsets, user access control, advanced logging and backup/versioning are just some of the many robust features included with DNC-Max.

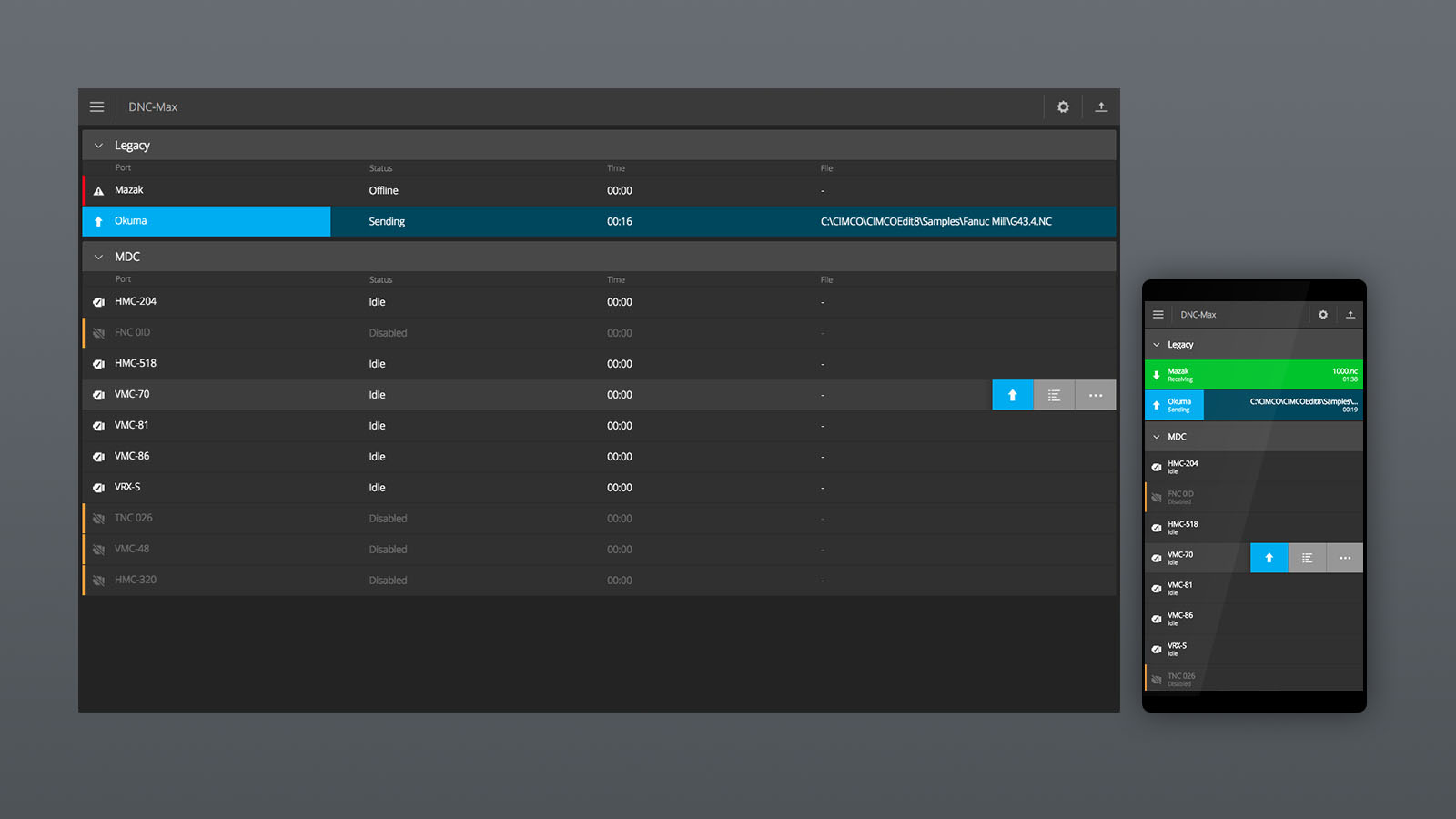

Unlike other DNC solutions, DNC-Max also boasts a professional look and feel. Designed to keep things simple while retaining easy access to advanced functions. Access DNC-Max from any desktop or mobile device using an intuitive interface that adapts perfectly to the device you are using.

Feature highlights

Client/Server architecture

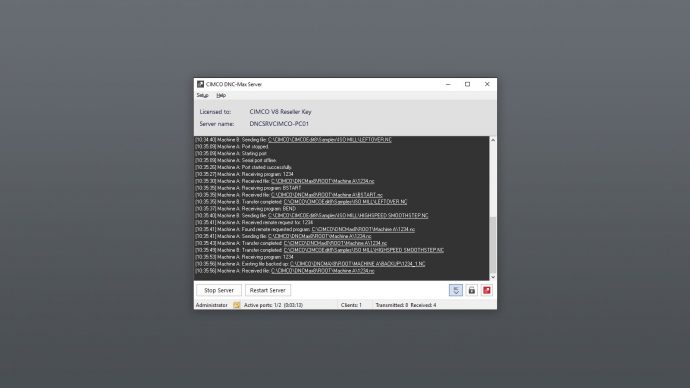

CIMCO DNC-Max is a Client/Server solution consisting of the DNC-Max Client, DNC-Max Web Client and DNC-Max Server. The DNC-Max Server is the core component of DNC-Max and handles all communication activities and calculations. It can be run as an application or as a service in the background as required.

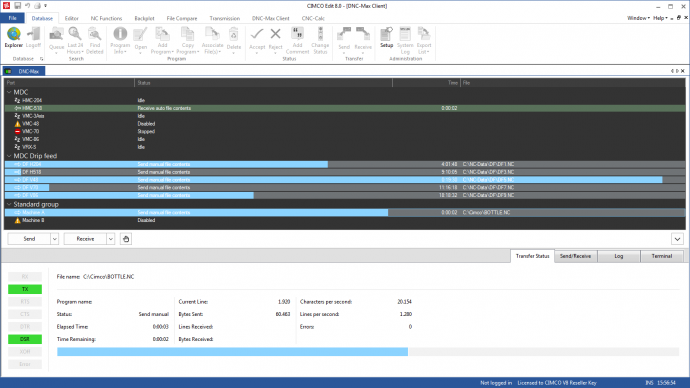

Powerful PC Client

The DNC-Max Client is the PC interface of DNC-Max and allows users to manage local or remote file transfers, monitor machine ports, and perform remote network configuration and administration of multiple servers – from a single point.

Next-generation Web Client (new)

The DNC-Max Web Client is a modern, browser-based application that works on mobile, tablet, desktop and TV. It supports local/remote file transfers, file preview, transfer queue, port organization and much more.

Seamless integration with CIMCO Edit

In addition to the stand-alone PC Client, the full DNC-Client is also available as an add-on for CIMCO Edit providing a seamlessly integrated application interface.

Advanced Remote Control

The advanced remote control features of DNC-Max allow operators to initiate program transfers directly from the CNC control or from a mobile device using the DNC-Max Web Client.

Programs, sub-programs and even entire directories can be requested in one operation directly from the CNC control – and for Ethernet controls it’s further possible to browse files directly on the server.

Any program changed by the operator and sent back to DNC-Max can be automatically raised in version or stored in a quarantine area. This gives you the ability to track changes and revert to any previous version if necessary.

CNC and hardware compatibility

DNC-Max is the complete DNC solution for all your CNC equipment. In addition to standard Fanuc/Haas style controls DNC-Max includes comprehensive support for Heidenhain, Mazak, Fagor, and many others.

DNC-Max works with off-the-shelf, industry standard RS-232 serial communications hardware, including Ethernet and Wireless serial device servers, traditional card based hardware, and existing legacy hardware.

DNC-Max supports 1 up to 4000 simultaneous ports for DNC or drip-feed when combined with industry standard RS-232 communications hardware from companies such as MOXA, Quatech, DIGI, and others.

Features

| Compatibility, software updates |

|---|

Compatible with your CNCsIn addition to standard Fanuc/Haas style controls DNC-Max includes comprehensive support for Heidenhain, Mazak, Fagor, and many others. |

Compatible with your filesWhether you set up your first system or replace an existing, the DNC application you choose must be compatible with your data. DNC-Max eliminates the need to update all your existing programs. |

Compatible with standard hardwareWorks with industry standard RS-232 serial communications hardware, including Ethernet and Wireless serial device servers, traditional card based hardware, and existing legacy hardware. |

+1500 point releasesUnlike any other DNC product, DNC-Max has been consistently improved over the past decade to meet increasing customer requirements. More than 1500 point releases since version 4. |

| Client/Server, configuration, port organization |

|---|

Dedicated Windows-based clientThe DNC-Max PC Client is the application used for local/remote file transfers, port monitoring and management. Access multiple DNC-Max Servers across a LAN, WAN or the Internet. |

Modern and responsive Web ClientThe DNC-Max Web Client is a modern, browser-based application that works on mobile, tablet, desktop and TV. Supports local/remote file transfers, file preview and port organization. |

Robust and reliable serverThe DNC-Max server supports up to 4000 simultaneous ports per server. Users can choose to run the Server as a service in the background or as an application. |

Single server or distributed solutionDepending on requirements, client and server can be installed on the same PC or multiple dedicated servers with thousands of clients accessing the servers across facilities. |

Most network protocols supportedDNC-Max supports a near complete range of both standard and specialized network protocols to communicate with most manufacturing equipment, including Heidenhain, Mazak, Deckel, Agie, Fagor, Brother, Modbus, and many more. |

Predefined and custom port templatesAdd new ports to your DNC system by selecting from a large set of predefined machine port templates or create your own. |

Port status and organizationThe DNC-Max clients present a tree-view of your available ports with clear status indications. Organize ports in groups and sub-groups for optimal overview. |

Port configuration across serversManage multiple servers from the DNC-Max Client across LAN, WAN, and Internet. Add, remove, configure or migrate ports, while server(s) are running. |

Parametric system configurationSystem variables and settings are utilized for rapid installation, configuration, and on-going system maintenance. Changes persist through-out the entire system. |

| Send, receive, remote request |

|---|

Send, receive and dripfeed programsSelect a port, program file(s) and click Send. Files are added to the Queue and transferred sequentially. Advanced options for unlimited filesize dripfeeding if supported by CNC. |

Transfer from line/block or tool changeTransfer from any point in a program. From line/block number or tool change. Tool changes, feedrate and spindle speed are monitored to ensure that correct tool and feed/speed is used. Supports mid-program restart in cases such as after tool breaks. |

Remote requestRemote request programs from the CNC control or mobile device. Supports DNC restart and file looping, extensive directory and sub-directory support, directory prioritization, filters, and wildcards. |

Barcode reader supportRequest the correct program files efficiently at the machine by scanning barcodes. Helps avoid typing mistakes, confusion and saves time. |

Auto-receive and namingConfigure and automate naming conventions and directories where incomming (received) files should be saved to. |

Parameter offsetsDNC-Max enables you to offset parameters in your NC program before it is sent to the machine. Specify your offset values and DNC-Max will automatically update your program. |

Supports FTP file transfersFull support for communicating directly with machines that support Ethernet TCP/IP FTP transfers. |

| Security, versioning, licensing |

|---|

User access controlControl the level of access users have on both server and client level limiting configuration and control options to key personnel. |

Logging and notificationsReal-time logging of DNC system and machine activity, and the ability to send status reports and notifications directly to CNC operators. |

VersioningPrograms that have been changed by an operator can automatically be raised in version or stored in a quarantine area. Easily track changes and revert to previous versions. |

License Server SupportFloating licenses allows you the flexibility of licensing only the exact number of applications needed for your unique system configuration. |