|

The program format for G33 Threading parallel (Constant Pitch) looks like this:

Program format: G33 X..., Z.... F...

X: Diameter of each treading cycle pass

Z: End point of threading

F: Thread Pitch

|

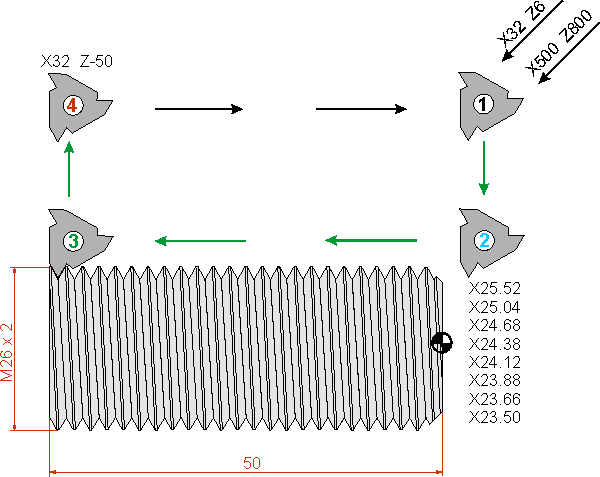

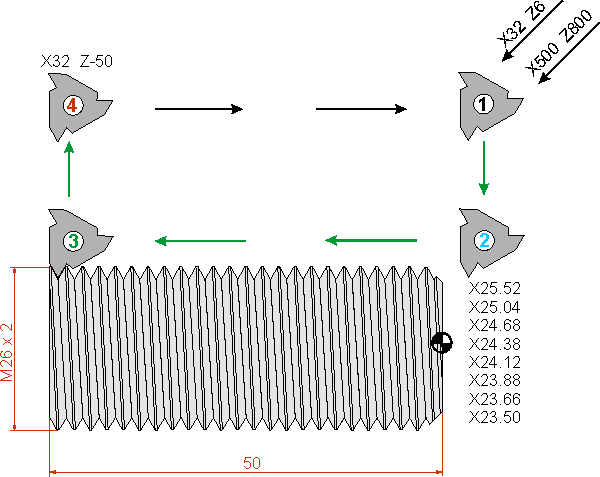

Description og steps in Threading Cycle (drawing) above:

1. The tool moves (1) at rapid traverse to the starting point of the thread cutting.

2. The tool moves (2) to the first X diameter position for Threading.

3. The tool moves (3) along the Z axis at the F pitch of the Thread synchronised with the spindle. (F2 for a thread pitch of 2 mm).

4. The tool moves (4) clear of the workpiece at the specified feed rate.

5. The tool moves (1) back to the starting point of the threading cycle at rapid traverse.

For each X position the cycle is repeated.

The number of extra passes at the final X position is dependent on the work piece material. Usually 2 passes are selected (Spring Passes).

At every X diameter the Cycle is executed.

For each new X dimension, the cycle is executed. The number of spring finishing passes at the final X diameter must be selected according to thread pitch, workpiece material, etc.

At each new X position the cycle is executed.

The number of spring finishing passes at the final X position must be selected depending on thread pitch, workpiece material, etc.

Program example with descriptions

| O100 | |||||||

| O100: Program | |||||||

| N10 | G00 | X500 | Z800 | ||||

| Tool Change safe position | |||||||

| N20 | G97 | G95 | S1400 | T0101 | M03 | M08 | M42 |

|

G97 Spindle Speed in rpm | |||||||

| N30 | G00 | X32 | Z6 | ||||

| Rapid to X32 / Z6 start position | |||||||

| N40 | G33 | X25.52 | Z-50 | F2 | |||

| G33 Calls the Threading cycle to perform moves 1 to 4 for each new X postion. X is the diameter where the cycle moves will take place Z is the end point of the thread. | |||||||

| N50 | X25.04 | ||||||

| N60 | X24.68 | ||||||

| N70 | X24.38 | ||||||

| N80 | X24.12 | ||||||

| N90 | X23.88 | ||||||

| N100 | X23.66 | ||||||

| N50 - N100: X at each new postion the threading cycle will make the 4 move pass. | |||||||

| N110 | X23.50 | ||||||

| X23.50 spring cut finishing pass | |||||||

| N120 | G00 | X500 | Z800 | M09 | M05 | ||

|

G00 X500 Z800 return to safe Tool Change position at rapid traverse | |||||||

| N130 | M02 | ||||||

| M02 Stop the Cycle and reset the control. | |||||||

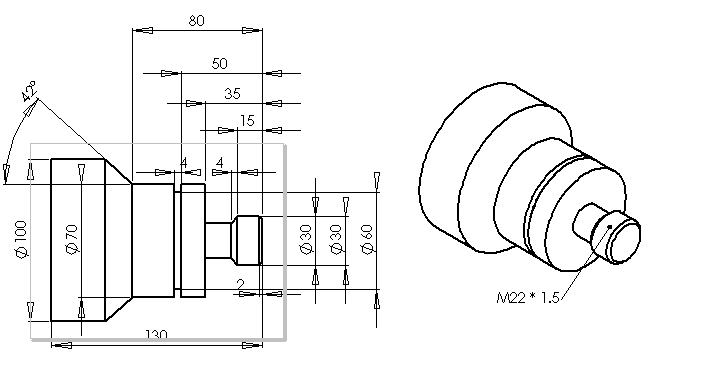

Prepare a program for the drawing below where a roughing is made with an external screw steel. Chipping depth must be 5mm in diameter. Then a finishing operation must be carried out with an external copy steel. Make an M30 * 1.5 mm thread using the G33 Cycle.

| Tool List | |

| Roughing Tool | T01 |

| Finishing Tool | T03 |

| Grooving Tool 4mm | T05 |

| Threading Tool | T07 |

| Speeds & Feeds | |

| Surface Speed for Roughing | 200 m/min |

| Surface Speed for Finishing | 300 m/min |

| Surface Speed for Grooving | 150 m/min |

| Fixed Speed for Threading | 800 rpm |

| Feed for Roughing | 0.25 mm/rev |

| Feed for Finishing | 0.20 mm/rev |

| Feed for Grooving | 0.07 mm/rev |

|