|

|

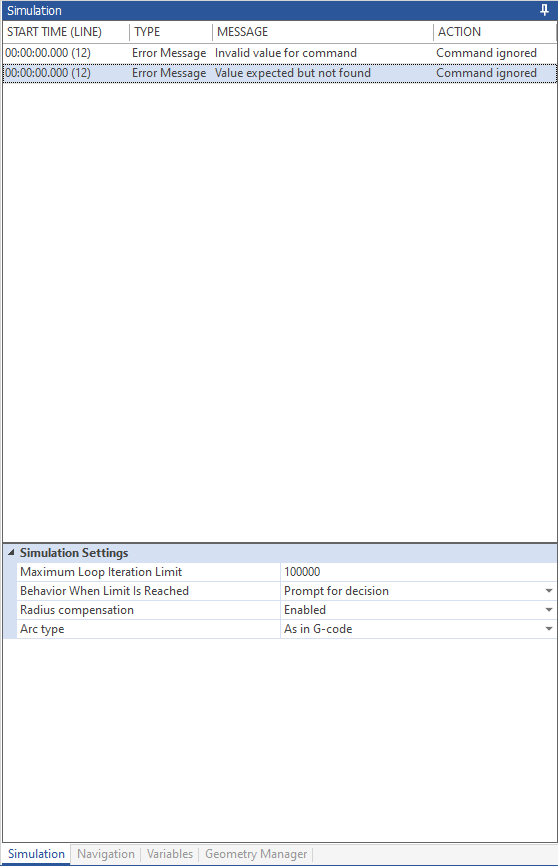

Simulation Report tab. |

This section describes the Simulation Report tab from the docking tab pane.

|

|

Simulation Report tab. |

The Simulation Report lists all program errors that have been detected within the NC program, including the line number the error occurs on, the type of error, a description of the error and the action taken. Once the program has been corrected, the Simulation Report will automatically update and remove the program errors.

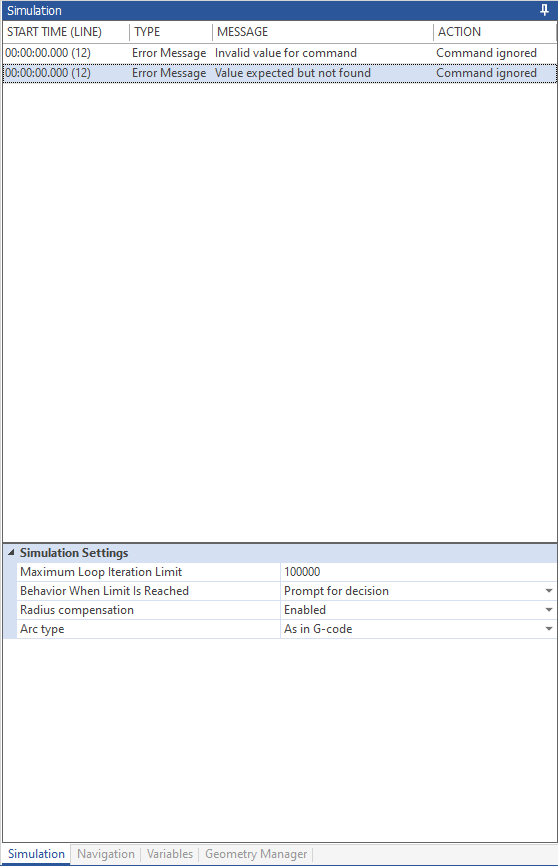

Select any program error from the Simulation Report and the corresponding line in the NC program, where the error was found, will be highlighted. The error will be highlighted.

|

|

Program error selected and corresponding line in program highlighted. |

This setting controls how many loop iterations will run before it is terminated.

This setting controls what will occur when the limit is reached. Options include, ‘Ignore the limit’, ‘Break out of the loop’ or ‘Prompt for decision’.

This setting controls whether radius compensation is ignored or not. It can be enabled or disabled.

Controls how to interpret the arc center specification.

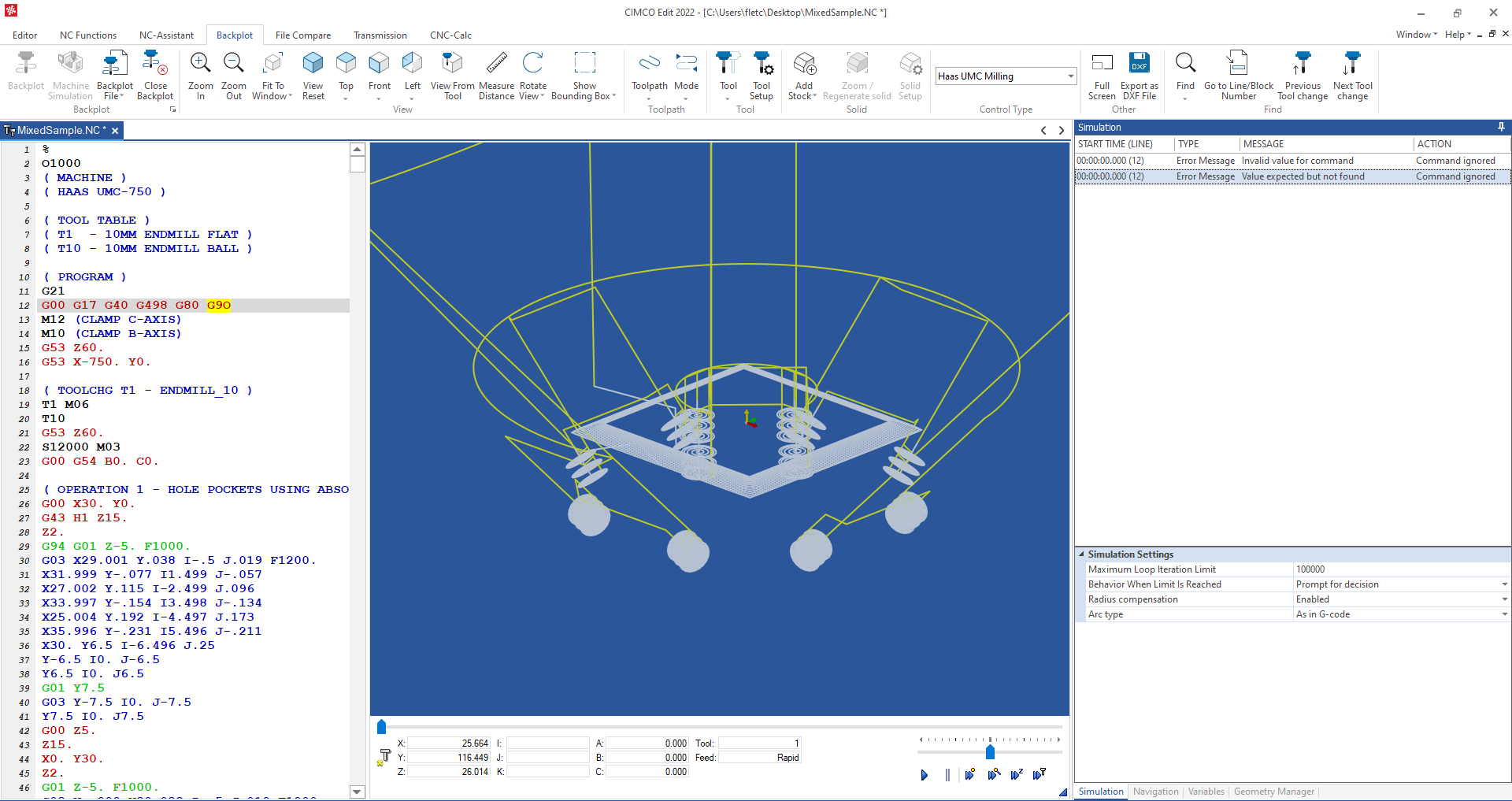

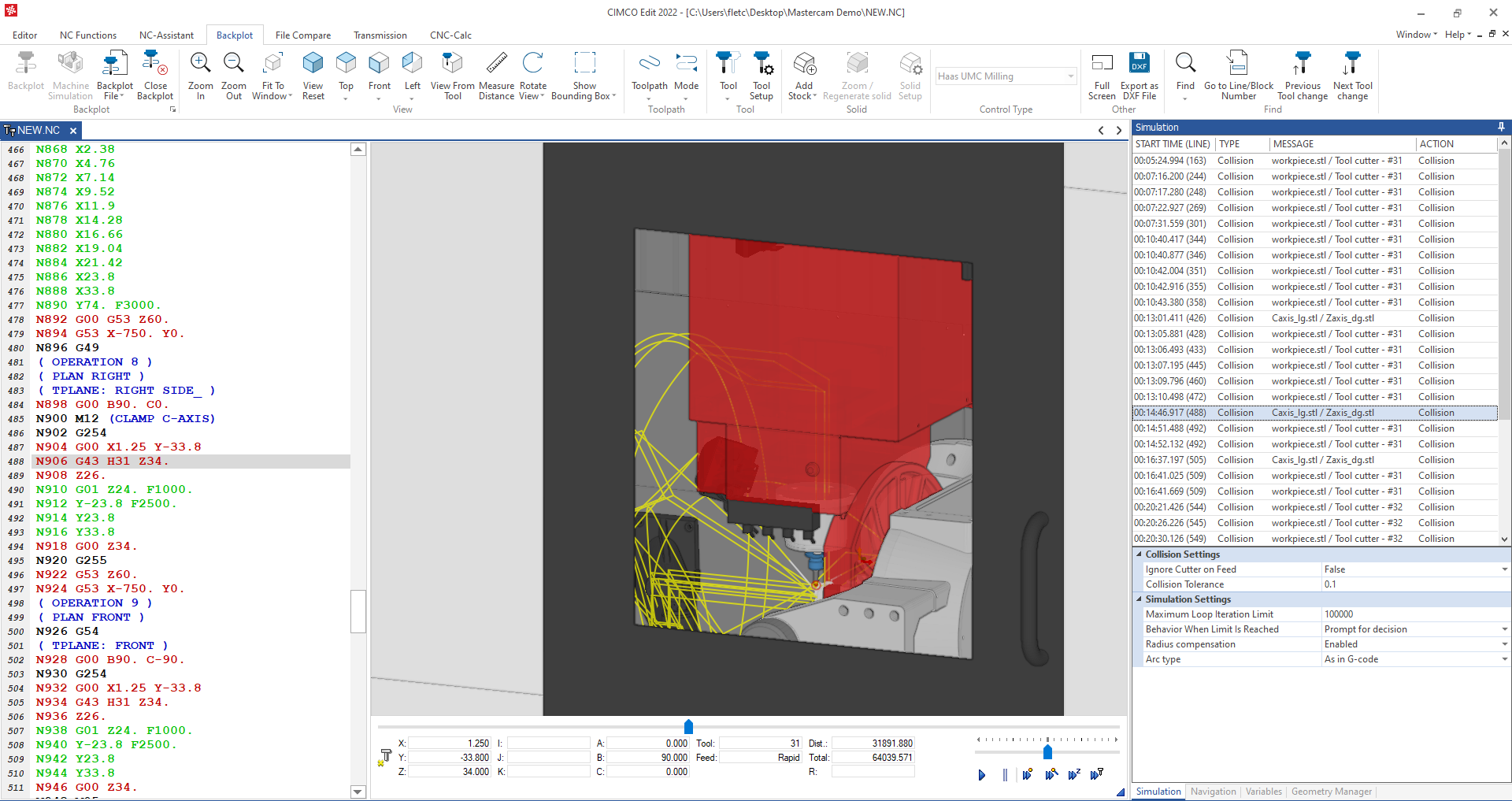

The Simulation Report provides information about collisions and limits when the Machine Simulation add-on is being used. Any component involved in a collision will be highlighted red in the Backplot window.

|

|

Simulation Report with additional options for the Machine Simulation add-on. |

This setting ignores the cutter when a move uses a rapid feedrate.

This setting controls the tolerance given to the checking of a collision. In the example above, collisions will be checked every 0.1mm of the toolpath.

|

|

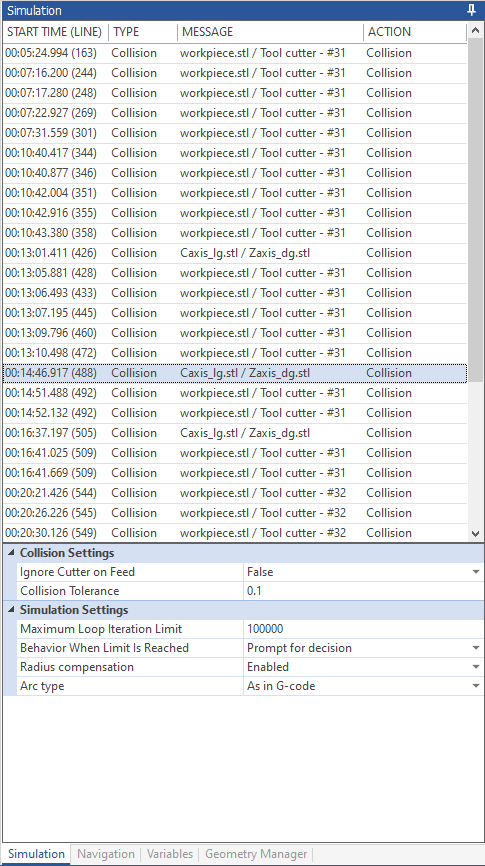

Collision with component highlighted in red. |